Case Study

Track Important Shop Floor Information with OnTakt

Ensure that information doesn’t get lost, misplaced, or misinterpreted

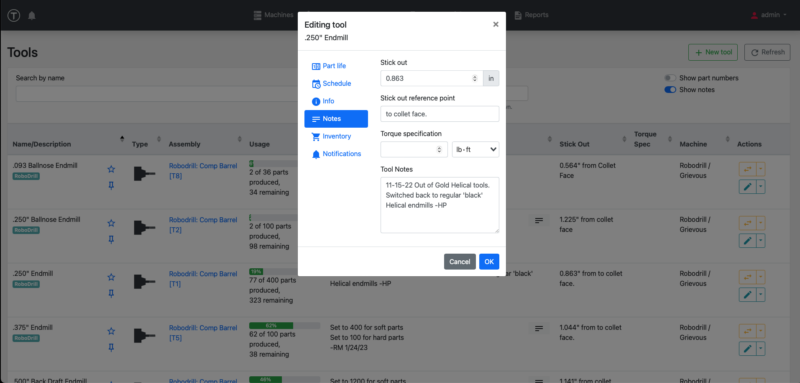

OnTakt is built to help your team capture in-process information to keep operations running smoothly. Enabling operators to add contextual information to tool changes, machine stoppages, scrapped parts and more helps retain knowledge across an organization and minimize errors and downtime in the future. By capturing key information that is accessible anywhere in your shop or office and making the data easy to access, operators aren’t left on the shop floor searching for setup sheets, guessing at machine setups, or incorrectly setting tool stickouts. Easily accessible data means fewer errors, a clearer understanding of the shop floor, and more productivity. Preventing one error a month easily provides an instant ROI.

Cost Savings with OnTakt

ROI year 1

ROI year 2+

Additional Case Studies

Save $1,400 tracking variables with OnTakt

Tracking historical data part by part can drive continuous improvement at your shop

Real-Time Notifications Reduce Machine Downtime

OnTakt Provides Both Preemptive and Instant Notifications Based on the Status of Machines and Tooling.

Return to Case Studies

Ready to get started?

Find out how OnTakt enables machine shops of all sizes to easily leverage data to increase productivity and profitability.