Quality and Traceability

OnTakt can provide traceability to capture, record, and access information that is critical to your quality system. Whether you are manufacturing under a general ISO9001 quality system, making aerospace parts under AS9100, or manufacturing medical devices under ISO13485, OnTakt can help track the data necessary for traceability.

Calculate the Cost of Downtime

When a problem or issue arises, OnTakt excels in pinpointing the exact starting point of the issue and can put boundaries on your issues to mitigate risk of items that have already shipped.

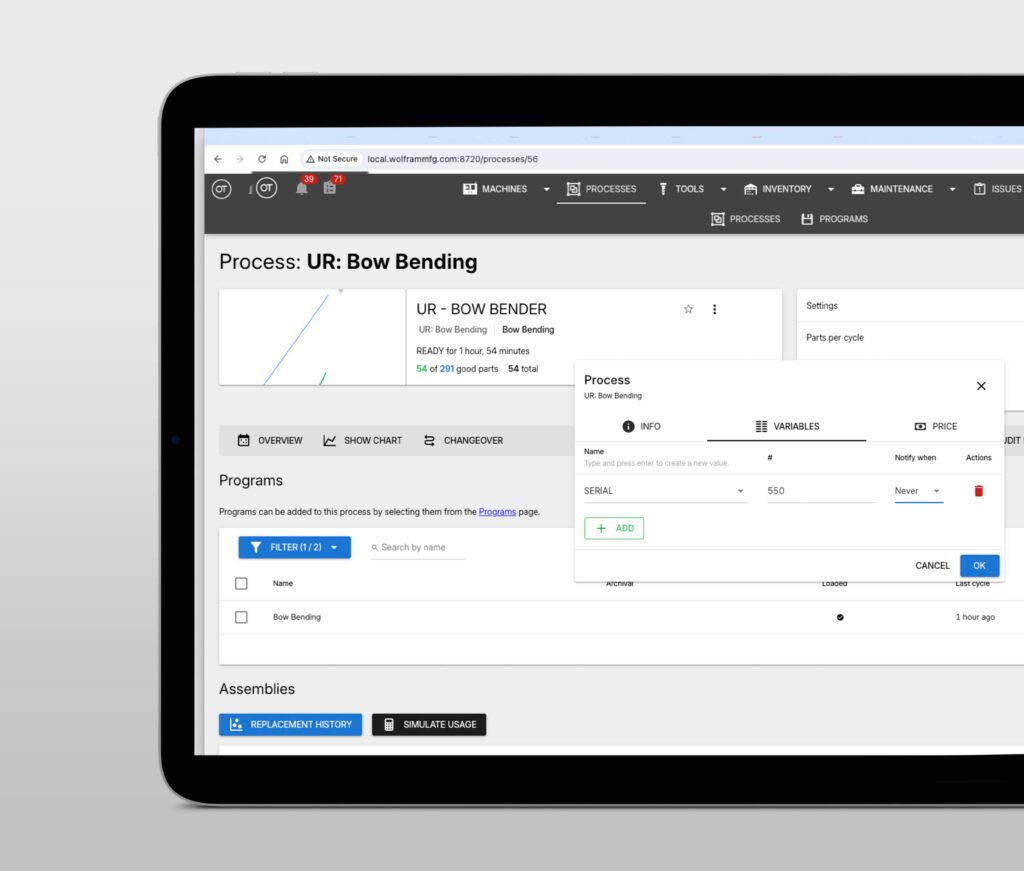

Track Serial Numbers

OnTakt can track serial numbers through the macro or common variables in your CNC’s control. Whether the data is added manually or input through other digital systems, we can capture, track, and provide historical records of the serial number of every part manufactured on your machines equipment.

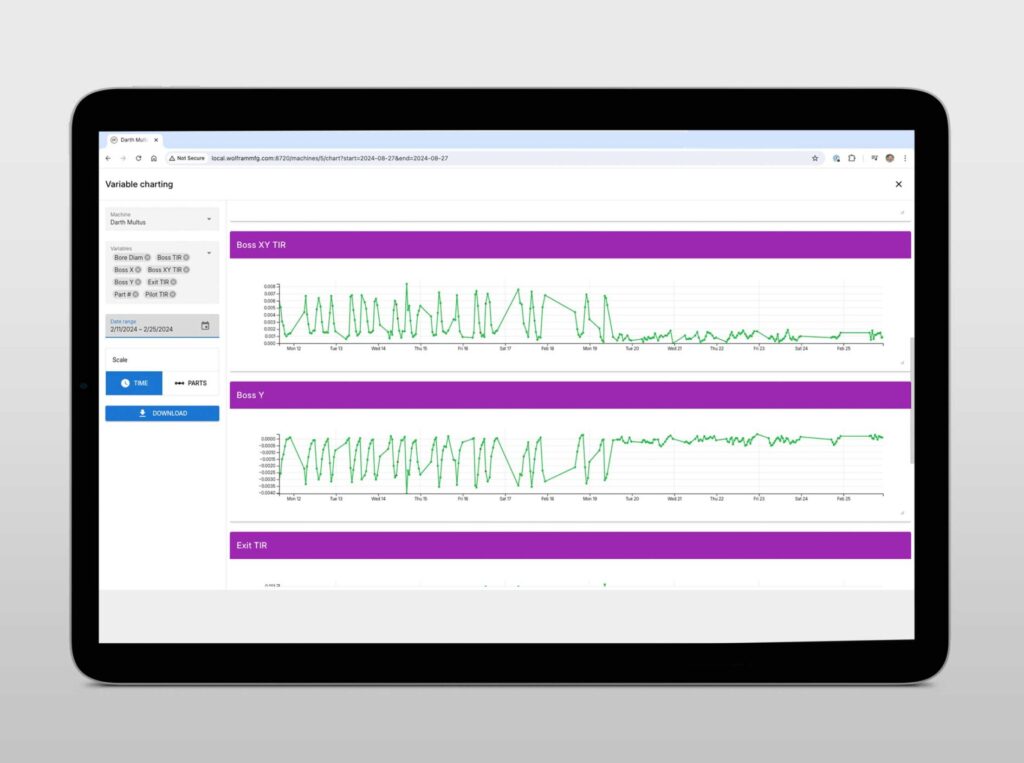

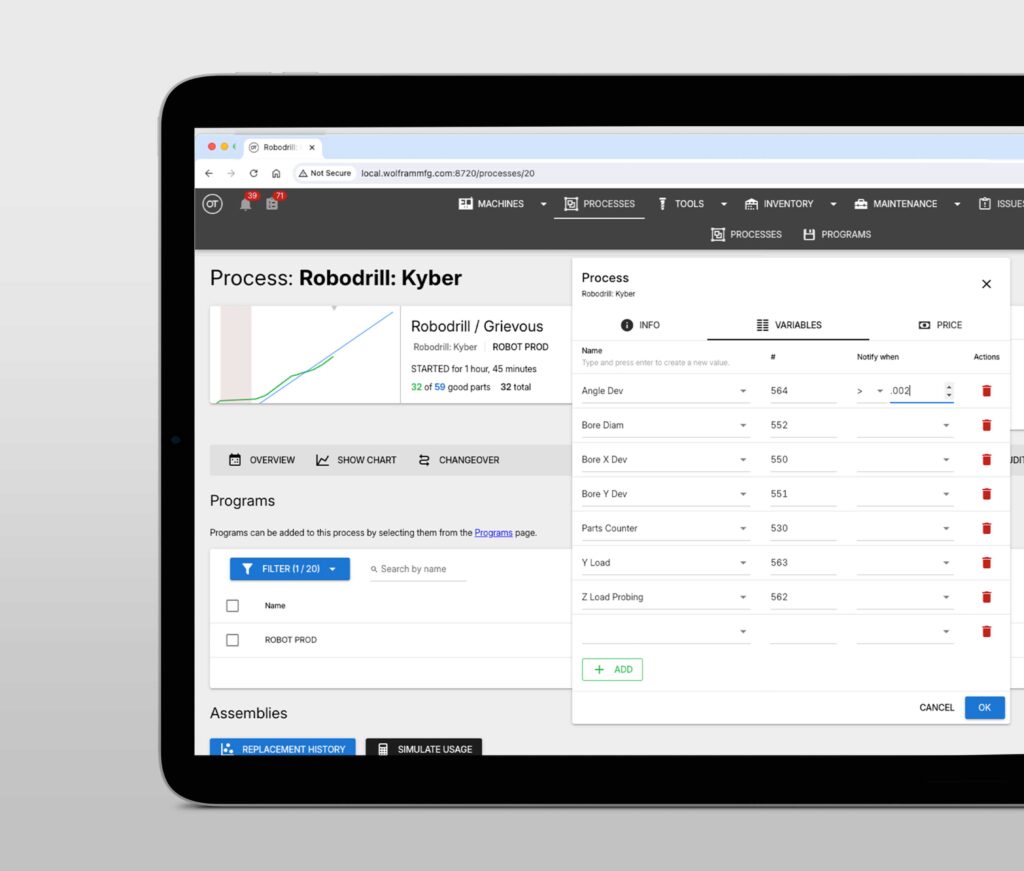

Track In-Machine Data

OnTakt can track in-machine inspection data from equipment like touch probes, scanning lasers, or other in-machine data collection equipment.

Tracking and storing in-machine inspection data provides a variety of benefits, including:

- Reducing the burden on operators to perform inspections

- Enabling one piece flow

- Identifying issues earlier in the process

- Providing notifications when dimensions are beginning to drift or past a preset threshold

Tracking in-machine inspections can also help identify opportunies for continuous improvement through your lean manufacturing initiatives.

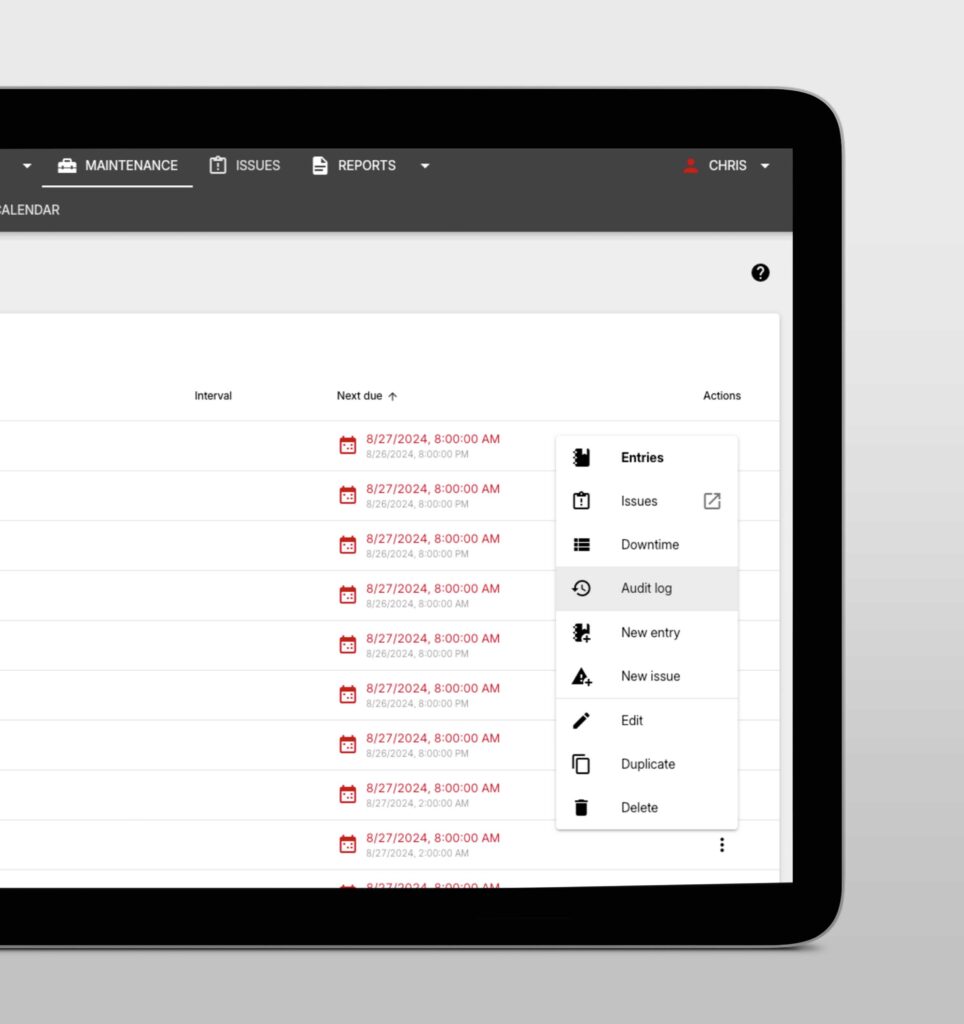

Auditing

OnTakt provides an auditing feature throughout the software. When critical actions are taken or important data is recorded, OnTakt tracks which user took the action. Additionally, an audit log is maintained when features of the software are changed are updated, including an undo function to revert accidental updates to the software.

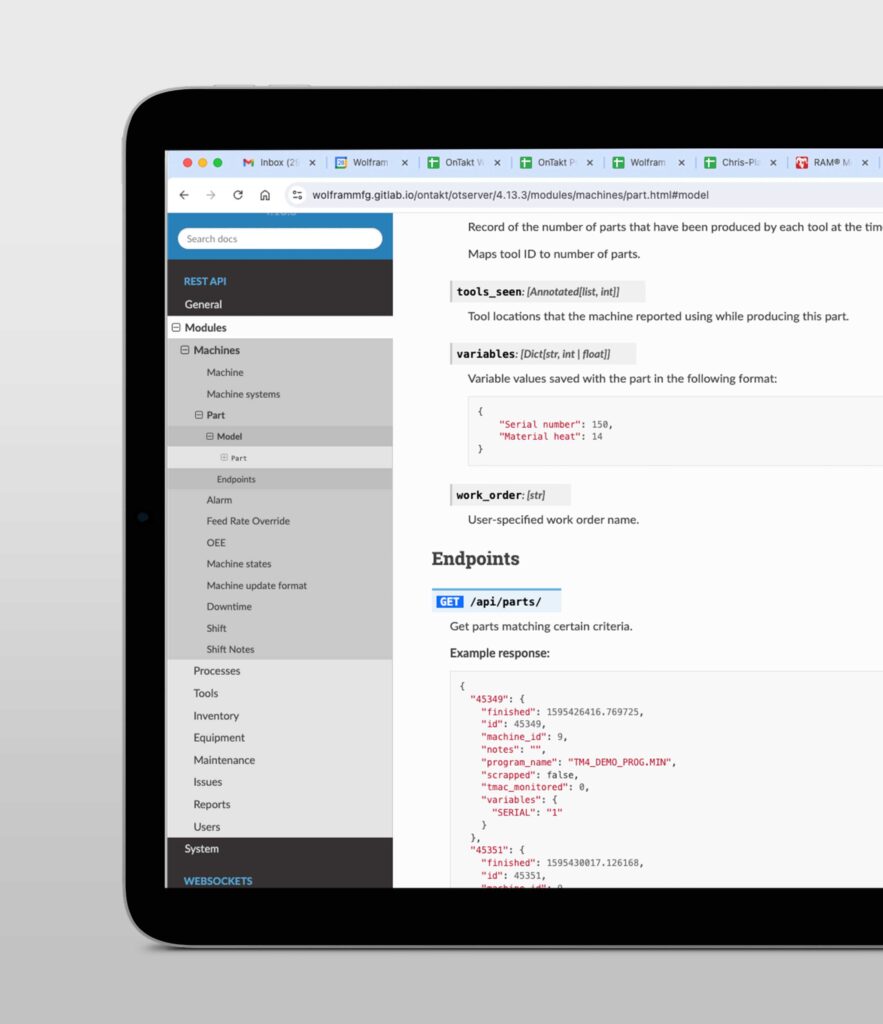

Using Direct API

Leveraging the OnTakt API can also enable you to pull critical data directly from OnTakt for use in other quality system software or Excel spreadsheets used for reporting dashboards.

With a direct API link or connection you can ensure that you get the correct data, in real time, that is less susceptible to operator interference, transcription errors, or other issues related to manual data capturing and reporting.

Ready to get started?

Find out how OnTakt enables machine shops of all sizes to easily leverage data to increase productivity and profitability.