Tribal Knowledge

Every organization seems to have that one critical employee with years of experience and company knowledge who knows what to do when problems arise. OnTakt can help extract that important tribal knowledge and record it historically so that anyone in your organization can access it and use it to make smarter decisions on the shop floor. OnTakt can help you capture tribal knowledge in 3 distinct ways.

Capture Historical Data

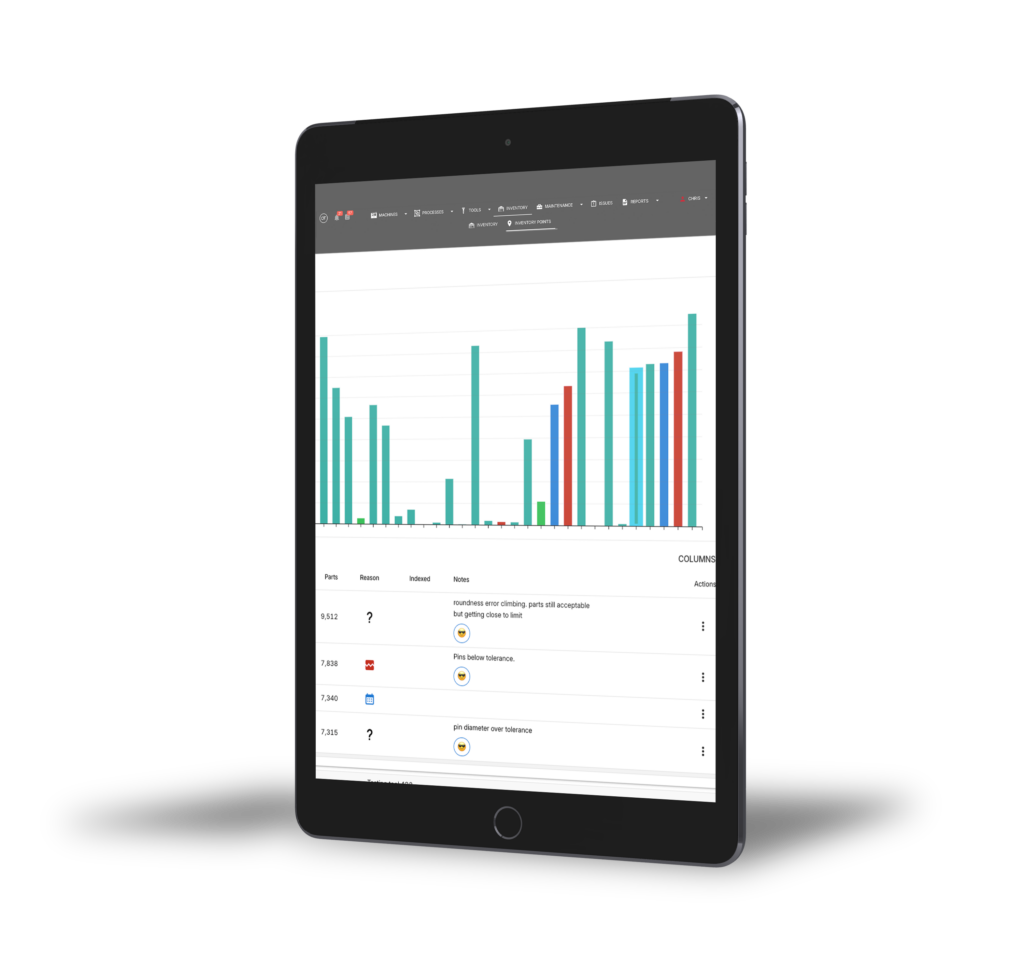

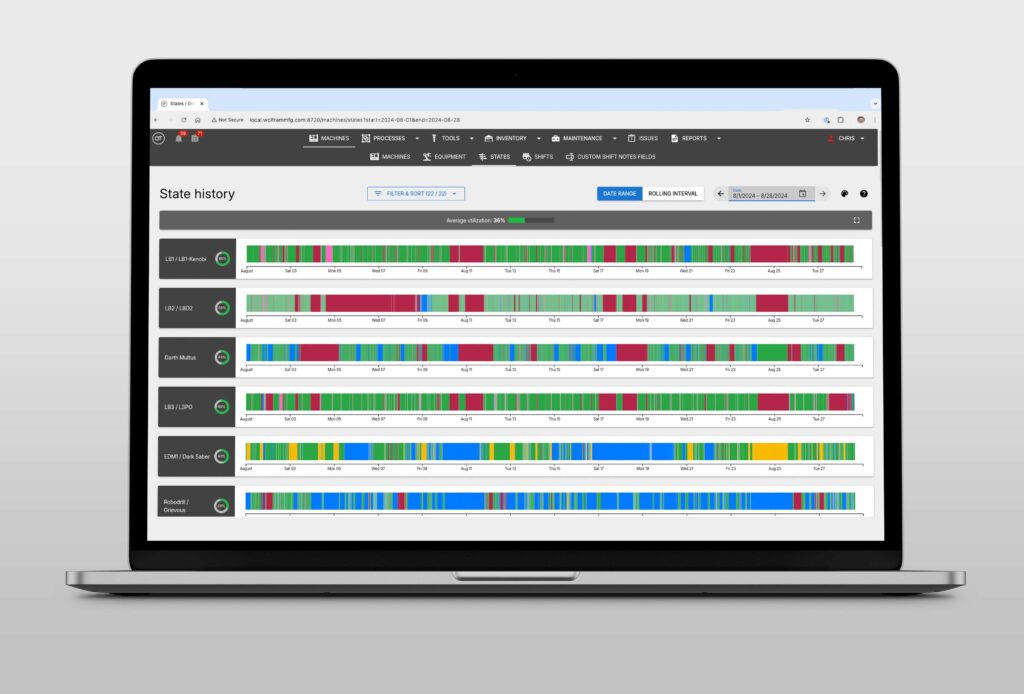

Like other machine monitoring software available on the market, OnTakt uses standard connectivity protocols like MTConnect, Focas2 and OPC-UA to capture, record, and visualize your machine data.

This allows you to understand how your machines have performed historically so that you can easily track the effectiveness of continuous improvement initiatives. Additionally, this historical view can give you insight into the past to identify when similar issues have happened and what the solutions were for those issues.

Easily Input Information

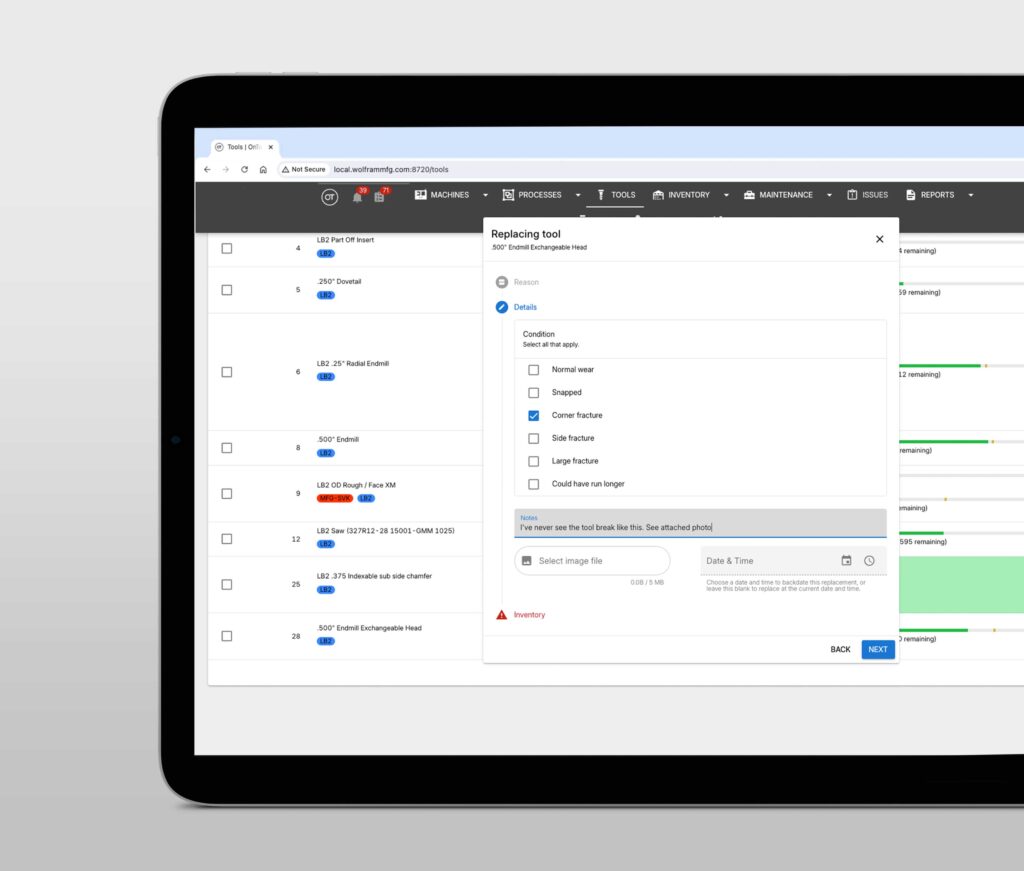

OnTakt stands apart as a complete production management solution, going beyond the typical machine monitoring software.

A major differentiator is its capacity to assist operators by providing key information about your processes without disrupting their workflow or requiring cumbersome data entry.

OnTakt enables operators to choose radio buttons or check boxes throughout the software. This enables operators to quickly provide valuable context about tasks like tool changes. A quick methodology for categorizing a tool change provides extremely valuable historical context for a tool.

Track Incidents with Notes

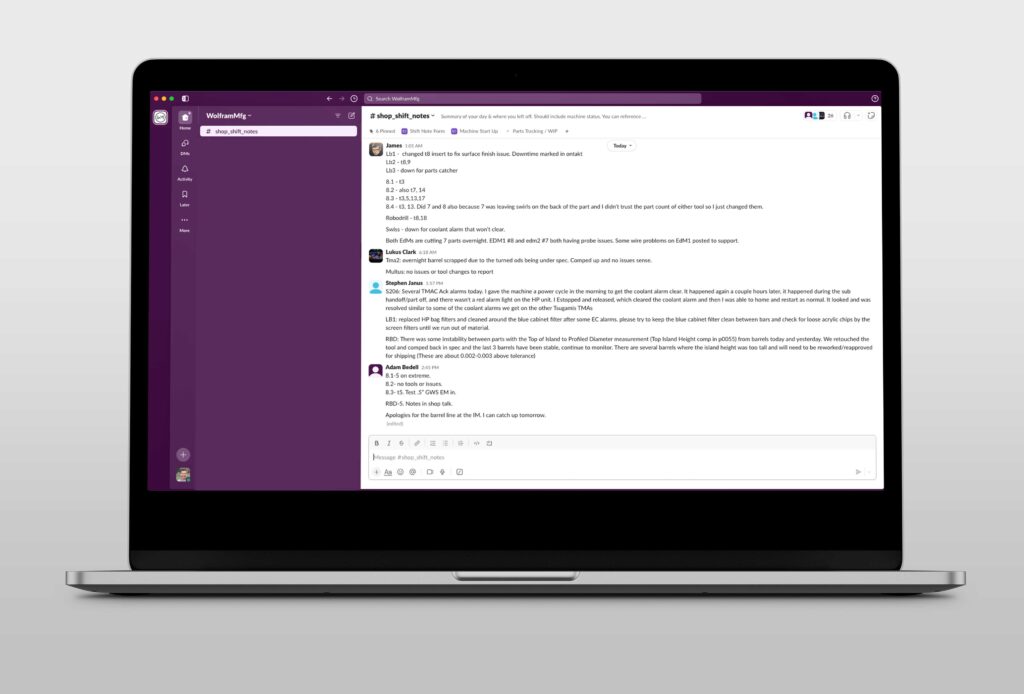

In addition to radio buttons and check boxes, Ontakt also includes the ability to add text when your team interacts with the software.

People often misremember information after an incident has happened. Circling back at the end of the shift or days after an incident often results in incomplete or incorrect information. Encouraging shop floor employees to add notes and context when an unexpected issue arises or something “looks different” provides exponential value when the engineering team is brought in to solve production problems.

Navigate Shift Changes

Effective communication during shift changes is crucial to ensuring parts run continuously as a new set of people hit the shop floor.

OnTakt’s shift notes feature allows your operators to easily input critical information so the entire team can see what to focus on for the next shift. When shift notes are completed they are sent out through MS Teams or Slack and can be accessed historically.

Ready to get started?

Find out how OnTakt enables machine shops of all sizes to easily leverage data to increase productivity and profitability.